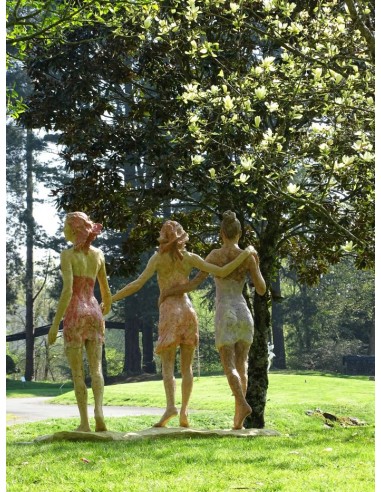

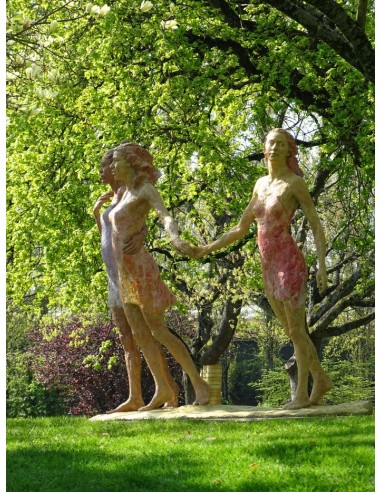

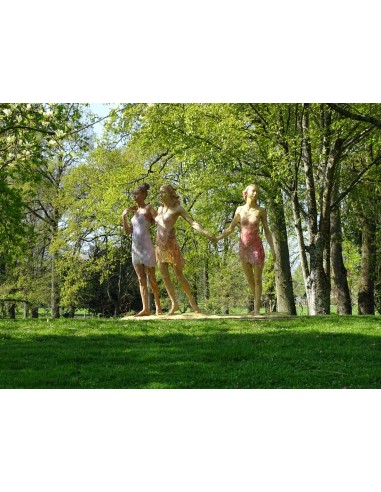

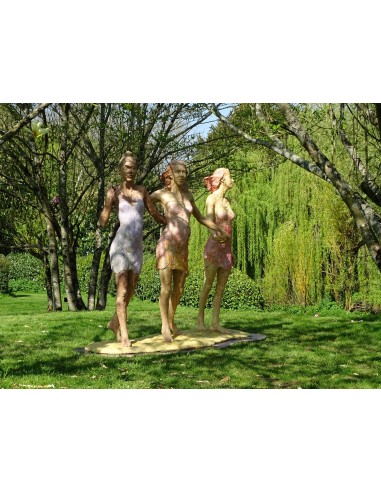

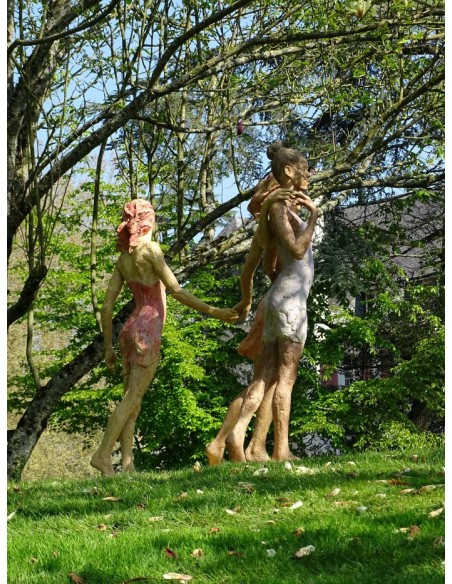

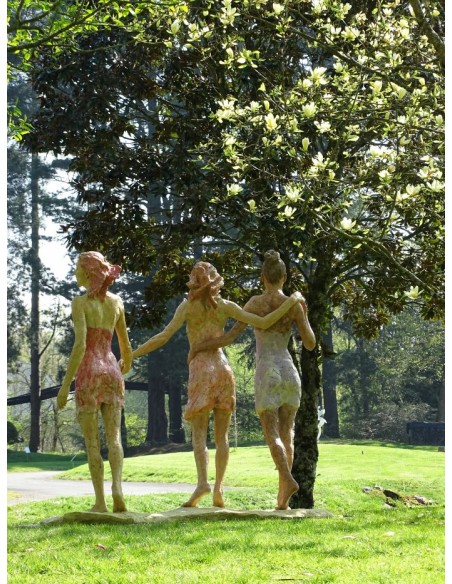

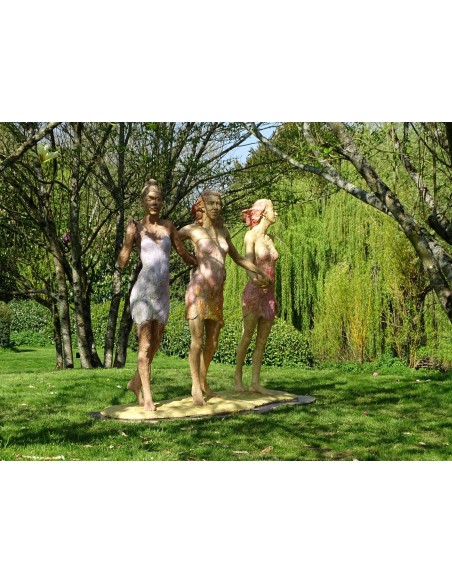

Spring Joy resin cast

37,980.00 €

Tax included

1 months after receipt of order

The damsels of Spring Joy, slender as flowers, rise to hoist themselves up and breathe the air of life. Together, they walk lightly. They dance towards their destiny, that of the unity of nations... with confidence and solidarity.

hight 195 cm

width 250 cm

depth 90 cm